- Have any questions?

- +91 98730 00860

- +91 98112 08210

- sales@milleniumpackaging.in

Strapping Machine Operations

Safety Instructions For Strapping Machines – Guide

November 13, 2019

STRAPPING MACHINE OPERATING CONTROLS AND OPERATING ADJUSTMENTS

November 16, 2019STRAPPING MACHINE OPERATIONS

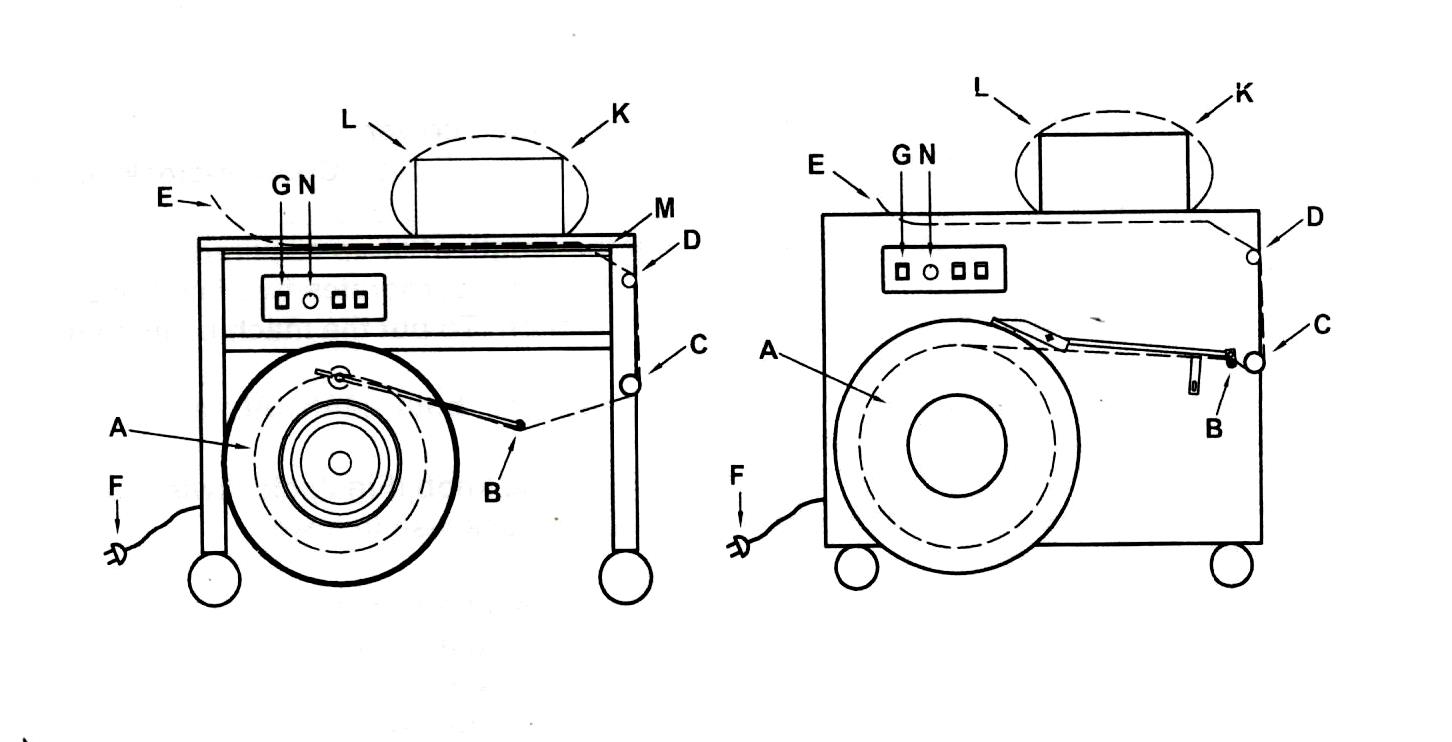

- Install coil (A) onto the dispenser.

- To install P.P strap coil, do the following:

- Prepare 6 – 15.5MM width strap, 200MM band reel.

- Loosen the dispenser handle and take off the outside dispenser disc. Load strap coil onto the dispenser (notice direction of strapping). Replace and tighten the outside dispenser disc.

- Open the table top of strapping machine. Thread strap through looper (B) in the take-up arm and pass through (C). Continue to thread strap between roller (D) and the guide.

- Continue to push strap between roller (D) and the guide until the end of the strap appears at point (E) in the table top. Close the table top.

- Connect power plug (F) to the power source.

- Set POWER SWITCH (G) to "ON" position

- Put your package (K) on the table top.

- Manually pull the strap (L) to encircle the package.

- Insert the strap end into slot (M). One strapping cycle automatically begins.

- After strapping, remove the package.

- Adjust STRAP LENGTH CONTROL (N) to feed length desired.

- Adjust strap tension if necessary. (refer to Section 2, strap tension

- Strap tension is adjusted according to the package being strapped. To adjust tension, proceed as follows:

- Strap a package to determine whether the tension is too loose or too tight.

- Set MOTOR and Power switches to “OFF” position.

- Loosen the tension screw in the Knurled knob which is used to adjust tension. Rotate the knob clockwise to increase, or counterclockwise to decrease tension.

- Tighten the tension screw.

Also Read, Know about strapping machine Operating & Adjustments